Functionality of Premium Water Pumps for Efficient Fluid Transport

In an industrial setting, pumping fluids has become an excellent premium, both for everyone who runs the company and the corporation itself. Whether it be clean water, chemicals, or waste fluids, the appropriate pump has to be selected to keep productivity up, downtime to a minimum, and safe operations within the premises. The malfunctioning pump brings the whole system down, and with it, time and money loss that would prove catastrophic in terms of safety. They are therefore gradually considering premium water pumps like the Grundfos pump. Their name alone is enough to guarantee performance and service reliability for long periods. Capable of delivering high performance on a wide range of rigorous tasks, these modern systems are built for performance, adaptability, and energy efficiency.

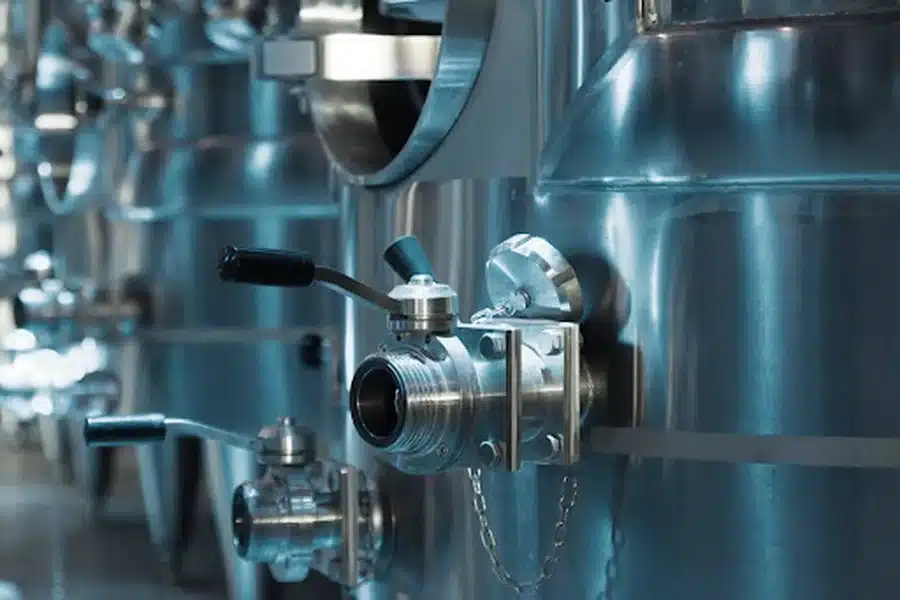

What Makes a Water Pump “Premium”?

Water pumps are not just for pumping water. At the higher end, they are constructed of high-quality materials, precision components, and smart design features that virtually guarantee long-term reliability and performance. They also include systems with corrosion-resistant housings, energy-efficient motors, and advanced sealing systems to minimize leakage during use and reduce wear over time from top brands like Grundfos, which leads in pump technology.

Indeed, pumps form another class of mechanical devices that also handle fluids-liquids, to be specific. As advanced as they are, the so-called premium water pumps can do things beyond pumping. They are constructed using high-quality materials, precision components, and smart design features that virtually guarantee long-term reliability and performance. A few examples of such brands include Grundfos, which leads in pump technology and offers systems with corrosion-resistant housings, energy-efficient motors, and advanced sealing systems to minimize leakage during use and reduce wear over time.

Key characteristics of premium pumps include:

- Long service life with minimal maintenance

- High energy efficiency for reduced operational costs

- Versatility in handling different types of fluids

- Precision control for accurate flow rates and pressure

These pumps are commonly used in chemical processing, wastewater treatment, HVAC, food and beverage, and pharmaceutical production. For example, a Grundfos circulation pump in an HVAC system ensures smooth, energy-efficient heat transfer, while a Grundfos circulating pump in an industrial plant supports stable flow rates for critical processes.

Types of Premium Water Pumps for Fluid Transport

There are several types of premium pumps designed to handle specific transport challenges. Each type offers unique advantages depending on the fluid properties, operational environment, and performance needs.

Centrifugal Pumps

Centrifugal pumps are used for the transfer of clear and lightly contaminated fluids. It converts rotary energy from a motor into kinetic energy, which pushes the fluid throughout the system. High-efficiency models like the Grundfos water pump are quiet and deliver dependable operation in continuous duty applications. These pumps are suitable for HVAC systems, irrigation installations, or general industrial water-moving applications. Their compact design with a high flow capacity makes them the preferred pumps for large-scale fluid transport where speed and volume are factors. Additionally, because centrifugal pumps have very few parts in motion, they require less maintenance over time.

Peristaltic Pumps

Perfect for viscous, abrasive, or chemically aggressive fluids, peristaltic pumps compress tubing through a roller mechanism to push fluid forward. These pumps are highly regarded in industries that require contamination-free environments and precise dosing, such as in chemical dosing and industrial wastewater systems. In these pumps, the fluid only comes in contact with the tubing’s inner surface, which minimizes cross-contamination and provides easier cleaning and maintenance. Such pumps are suited for laboratories, chemical plants, and food processing facilities requiring hygienic and accurate fluid delivery. Moreover, operational flexibility arises from self-priming functions and dry-run capability.

Diaphragm Pumps

The diaphragm pump operates by using a flexible membrane to transfer fluids and is especially suited to corrosive or dangerous applications. Their ability to accomplish a leak-proof operation makes them ideal for chemical handling and wastewater applications. The pumps process slurries, viscous fluids, and even fluids with solid particles without compromising performance. Commonly used for pharmaceutical manufacturing, oil and gas operations, and industrial cleaning systems, diaphragm pumps have also achieved excellent metering precision and can handle high pressure- truly an all-encompassing fluid control choice for arduous applications.

Applications of Premium Pumps in Industry

Premium water pumps are used in a wide range of industries:

Wastewater Management

Essential within the wastewater treatment, premium water pumps could, with steady and reliable efficiency, deal with viscous sludge, chemical dosing, and recycling of water. Peristaltic and diaphragm pumps are especially helpful in this regard, as they transport abrasives and chemically active fluids without clogging. These pumps are also excellent in controlling flow without approximation, which is important when dealing with dosing agents and pH balancing. They can withstand and endure tough operating conditions, which significantly reduces maintenance needs and limits post-service programs to very few years.

Chemical Processing

In chemical processing applications, pumps are supposed to meet stringent requirements in safety, accuracy, and chemical compatibility. Premium water pumps should be able to pump aggressive, volatile, or temperature-sensitive liquids while maintaining the ability to withstand leakage and degradation. Peristaltic and diaphragm models are often favored for this type of operation due to their contamination-free design, followed by a linear flow. Their capability of pumping corrosive materials promises both process efficiency and operator safety.

Food and Beverage

Meeting the highest standards of hygiene, yet performing and durable, pumps are called for in this industry. These are the peristaltic pumps that are high-end and used for the transport of sauces, dairy products, juices, and other consumables without compromising taste or purity. It is simple to prevent cross-contamination since, in the case of peristaltic pumping, only the inside of the tube is in contact with the fluid, and cleaning becomes easy. These pumps also accommodate gentle flow, ensuring that the texture and quality of delicate ingredients are maintained.

HVAC and Heating Systems

Reliable circulation of fluids is pertinent for stabilizing temperature within heating and cooling systems. The Grundfos circulation pump and Grundfors circulating pump are solutions offered in this area, with the notable design of being energy-efficient and quiet in operation. They provide consistent heating and cooling in residential as well as industrial buildings. More advanced models adjust their flow rates according to actual system demand and ensure energy conservation and reduced operating costs.

Mining

In the mining industry, pumps must endure highly abrasive and high-solid-content fluids such as slurry and tailings. Premium water pumps, especially peristaltic and diaphragm models, are favored for their robust construction and self-priming capabilities. They can operate under extreme pressure and temperature variations, making them reliable tools in demanding environments. Their ability to transport fluids without clogging ensures uninterrupted operation and minimizes downtime.

Final Thoughts

To guarantee safe, efficient, and cost-effective fluid handling, premium water pumps such as the Grundfos water pump are worthy investments. The systems are designed to minimize downtime, increase reliability, and maintain consistent performance, even under the most demanding conditions. Whether you require the accuracy of a Grundfos circulating pump for flow control or a rugged solution for industrial wastewater applications, choosing your pump wisely is an investment in the long-term success of your operation. To view options for high-performance pumps suited specifically to your needs, check out AMED’s full range of Pumps and Peristaltic Pumps. Our advanced solutions are designed for fluid transportation that is efficient, reliable, and ready for the future.