Warehouse Construction: What You Need to Know Before You Start Building

The logistics and online shopping world is exploding right now, and there’s real money to be made if you invest in a warehouse. It’s one of those opportunities that doesn’t come around often, so if you’ve been thinking about it, now is the best time to act.

But warehouse construction isn’t something you should take lightly. Many people have already made the mistake of thinking it’s just another building project, only to find that it ended up costing them more.

The reality with warehouse construction is that you’re creating the backbone of an operation that needs to work perfectly under serious pressure. And that means getting the right people involved from day one. You’ll need architects who actually know industrial spaces, engineers who understand what it takes to handle heavy loads, and various specialized contractors. Sometimes you’ll even need specific expertise, like a copper roofing contractor, if your project calls for it.

So, before any work gets underway, here are a few things you need to pay attention to.

What Makes Warehouse Construction Different?

Regular commercial buildings are designed around people, making customers comfortable and keeping employees happy. Warehouses? They’re built around performance. These buildings must handle massive weight, keep products moving efficiently, and work with complex systems such as storage racks, conveyor belts, and the automated equipment that’s becoming increasingly standard these days.

When constructing a warehouse, your end goal is simple: build something secure and functional that’ll keep making you money for years to come. But getting there? That’s where understanding the process really matters.

Different Kinds of Warehouses

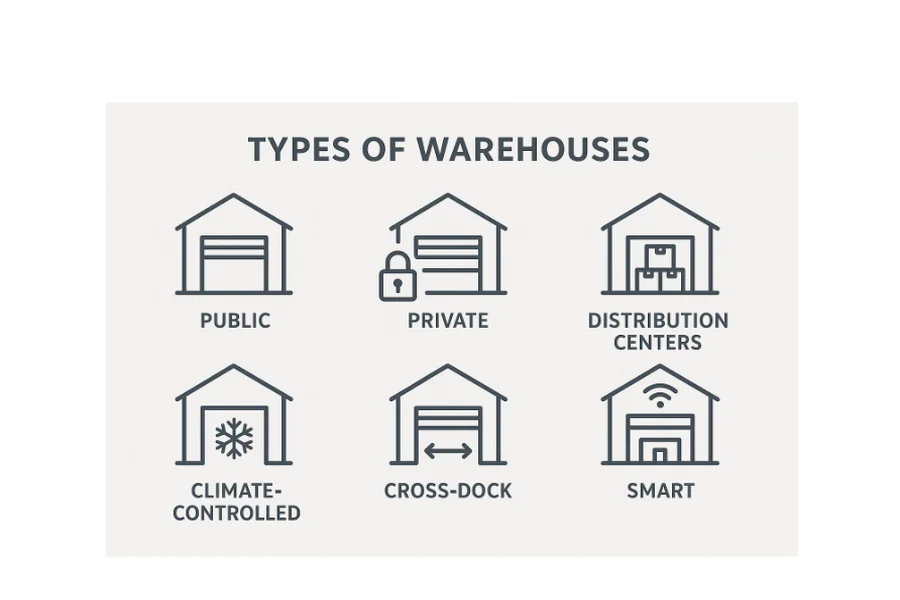

Not all warehouses serve the same purpose. The best type depends on what you store and how your business works:

- Public Warehouses: Owned by public or semi-public groups and rented to different companies. Great option if you own a smaller company or have fluctuating storage needs.

- Private Warehouses: Owned by a single company (such as a large retailer) for their own use. With this option, you get full control, but pay more.

- Distribution Centers: Built for speed, these warehouses are suited if you move goods directly from incoming shipments to outbound delivery with minimal storage time.

- Climate-Controlled Warehouses: Ideal if you store perishable goods or electronics that need special temperature or humidity conditions.

- Cross-Dock Warehouses: Meant for quick storage, as goods move straight from delivery to shipping.

- Smart Warehouses: Powered by advanced automated systems, including robots and sensors, and often used by big e-commerce companies.

Is It Better to Build or Rent a Warehouse?

To build or rent is one of the first decisions you need to make when it comes to warehousing.

Both choices offer advantages and disadvantages and are contingent upon your business requirements, available funds, and future goals.

Building vs. Renting: Pros and Cons

If you build, you get to plan every detail and create a space that fits your business perfectly, and you own the property, which could go up in value. But building costs a lot upfront, takes time, and you’re responsible for repairs, insurance, and taxes.

Renting usually means lower startup costs and more flexibility. You can move in faster and switch locations easier as your needs change. But you don’t get to decide every detail, rents can go up, and you don’t own anything at the end.

Timeline, Flexibility, and Control

Expect the process to take several months or longer, potentially exceeding a year, if you opt to build a warehouse. That being said, you’ll need to plan ahead. Renting, on the other hand, means you can adjust faster as your business grows or shrinks.

Put simply, building gives you total control over the plan, technology, and systems, while renting limits what changes you can make.

Key Things to Check Before You Build

Before construction starts, you need to check several important points. Skipping any of these can cause expensive problems later.

1. Choosing the Right Location

Location is more than just finding land. It’s about being close to highways, train stations, airports, suppliers, and your main customers. Good locations often cost more but save on transport and delivery costs.

If you pick a cheaper, out-of-the-way place, you might lose money in other ways. It’s smart to study traffic and shipping routes before making a decision.

2. Buying Land and Checking the Site

When you pick out land, check the ground and soil conditions, look for environmental risks, and add up all costs.

A careful site check helps you avoid future trouble and figure out the best way to place the building. Rocky or unstable land can raise costs for foundations and site work.

3. Following Local Rules and Getting Permits

Local laws control what you can build and how. There are limits on things like size, height, parking, and effects on the environment. Getting all approvals takes time, so include this in your planning. Talk with local officials early to avoid surprises.

4. Thinking About Environmental Impact and Saving Energy

Today, new warehouses often include ways to use less energy and reduce harm to the environment. Using recycled materials, installing energy-saving heating and lights, taking advantage of sunlight and fresh air, and even adding solar panels are good ways to keep running costs low and show good corporate responsibility.

Concrete buildings help stabilize temperature and can lower your energy bills.

5. Planning for Growth Later

Try to prepare for changes as your business grows. You can buy extra land next door, design your warehouse for easy expansion, or use movable shelves that let you reshape the space as needed.

Who Builds Your Warehouse?

The people who plan and build your warehouse play a big part in whether the project goes well.

Who You Need: Architects, Engineers, and Contractors

A solid team includes architects (who design the structure), engineers (for everything from the building’s strength to the mechanical and electrical systems), and a main contractor, who manages the builders and schedule. Specialists for heating, cooling, automation, and electrical work are also important.

Hiring the Right Experts

It’s important to choose builders who know warehouses. Check their past work and references. Pick a contractor who understands what warehouses require and who has a record of finishing jobs safely and on time.

Working Together and Communicating

Good teamwork and communication between the owner, managers, builders, and all subcontractors keep things moving and avoid mistakes. Using tools like project tracking software helps everyone stay on the same page.

How Warehouse Construction Usually Goes

The time it takes can depend on the size and details, but most warehouses follow a standard process.

A simple concrete warehouse often takes 4-6 months, but bigger or more complicated ones need more time.

1. Site Prep and Early Steps

First, do in-depth planning, complete designs, secure money, get permits, and hire your team. Next, clean the land, level it, and set up drainage, utilities, and any temporary construction needs. This can take a few weeks.

2. Laying Foundations and Building the Structure

Once ready, start laying the foundation–usually a concrete slab. After it hardens, begin putting up steel frames or concrete walls. This step often takes the most time.

3. Setting Up Main Systems (Heating, Electric, Plumbing)

As the frame stands, install electrical wiring, lighting, plumbing, and HVAC systems for heating and cooling. They need to be efficient and safe.

4. Finishing the Inside

Put in insulation, interior walls for offices or break rooms, finish the floors, and paint. Install racks, cold storage (if necessary), and other key structures.

5. Final Checks and Handover

Inspectors will check that everything meets codes. If problems show up, they must be fixed. Once everything is approved, you get a Certificate of Occupancy and can start using your warehouse.